Applications for stereolithography

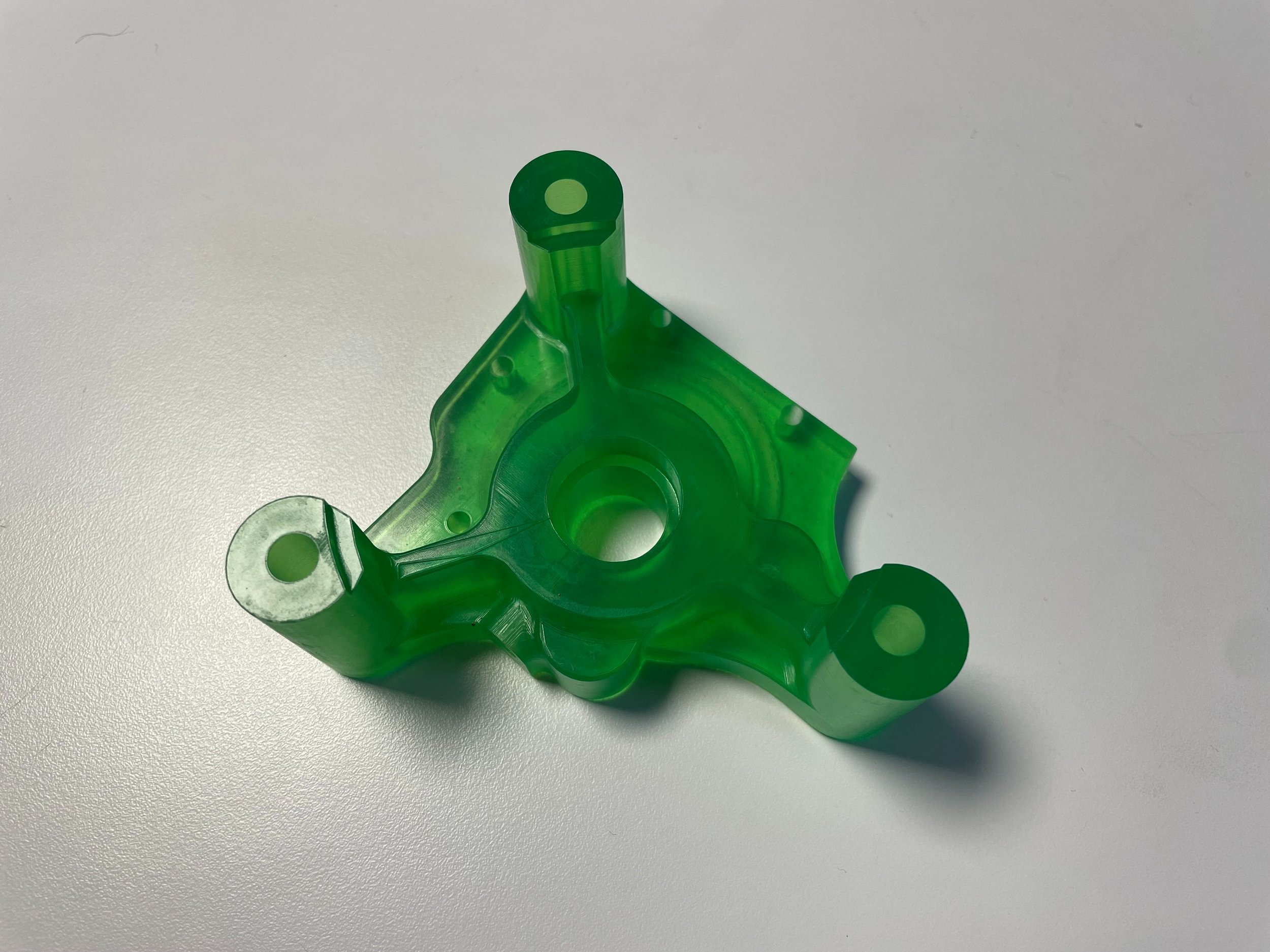

Direct Tooling

SLA enables the direct production of tooling inserts, molds, and patterns, eliminating the need for traditional tooling methods. SLA direct tooling facilitates the creation of injection molding inserts for cost-effective and quick turnaround low-volume production. Manufacturers use SLA-printed tooling aids in producing layup molds and patterns for complex parts in composite manufacturing. Consumer goods industries benefit from SLA direct tooling by creating custom molds for casting, thermoforming, and vacuum forming processes. With SLA direct tooling, manufacturers can reduce lead times, lower costs, and quickly iterate on tooling designs, resulting in improved overall production efficiency and accelerated time-to-market.

Jigs & Fixtures

The high precision and versatility of SLA allows for the rapid production of customised jigs and fixtures tailored to specific manufacturing needs. Our large scale SLA enables the creation of assembly line jigs, alignment tools, and gauge fixtures to ensure precise and efficient manufacturing processes. The quick turnaround and cost-effective production of jigs and fixtures enhances productivity, improves assembly accuracy, and streamlines manufacturing operations.

End-use

End-use parts produced using SLA offer numerous advantages in various industries. SLA technology enables the direct production of functional, high-quality parts with intricate details and complex geometries. In automotive manufacturing, SLA end-use parts include interior components, lighting assemblies, and custom brackets. Additionally, SLA end-use parts find applications in healthcare, including prosthetics, surgical guides, and custom medical devices. With SLA, manufacturers can achieve faster production, customization, and cost-efficiency, making it a valuable solution for creating end-use parts across a wide range of industries.

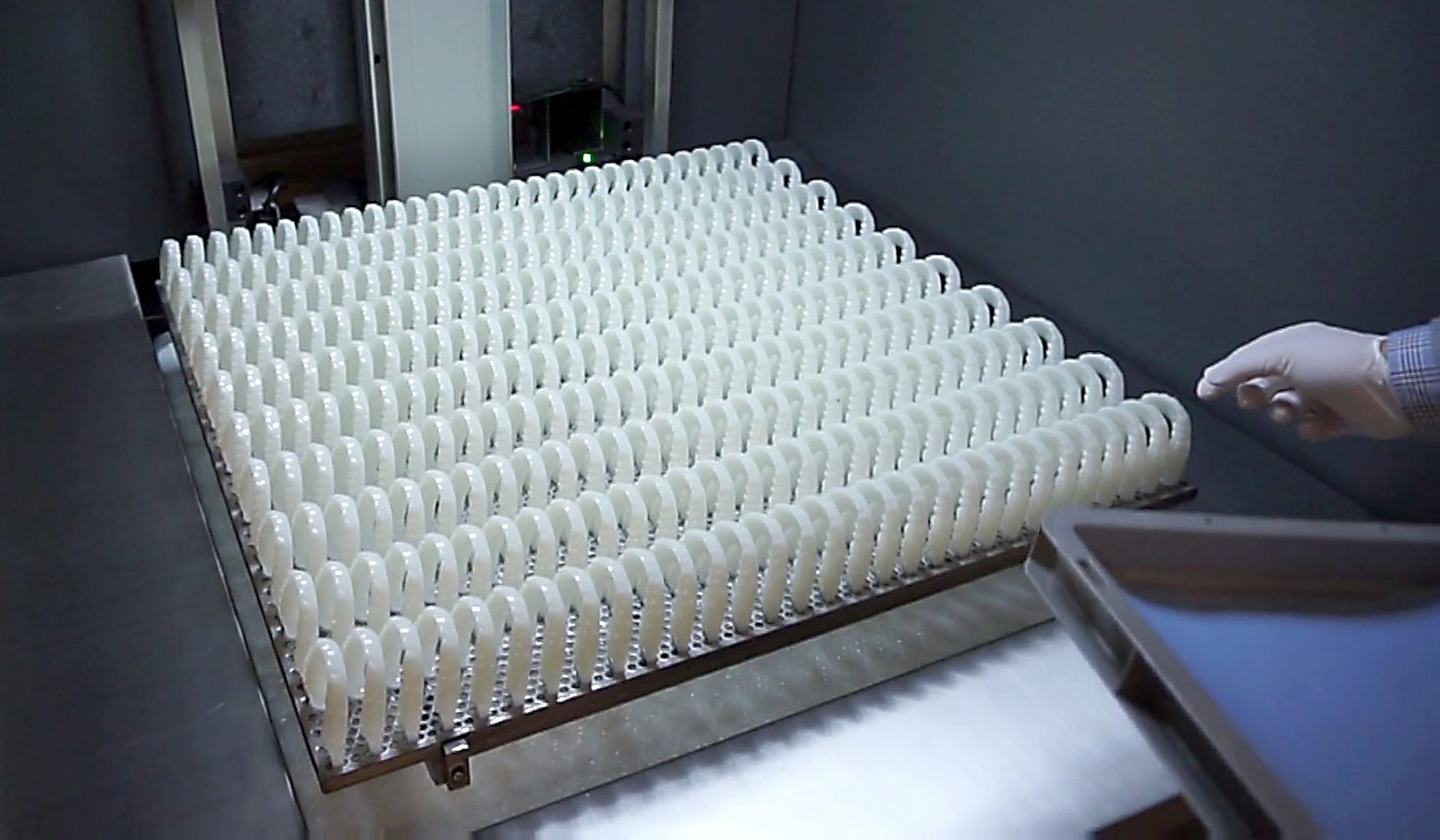

Prototyping

Prototyping applications with stereolithography (SLA) offers numerous advantages over other 3D printing technologies. As well as faster print speeds, stereolithography offers superior accuracy and repeatability enabling prototypes to be produced with the highest of quality, achieving exceptional results even with highly intricate parts and complex geometries. This enables the finished part to most accurately represent the desired end-product whilst also providing the capability to act as a functional prototype, enabling more effective testing and product viability before moving to full-scale production, leading to accelerated innovation and improved design iteration.

Casting

Casting applications utilizing stereolithography (SLA) technology offer numerous advantages in diverse industries. SLA enables the production of high-resolution patterns and molds for various casting processes. SLA can be utilized to create investment casting patterns for engine components, transmission parts, and other complex geometries. SLA facilitates the production of intricate casting molds for turbine blades and structural components. Industries such as jewelry, art, and sculpture benefit from SLA's ability to create detailed wax patterns for investment casting. By leveraging SLA for casting, manufacturers can achieve faster turnaround times, intricate designs, and improved casting accuracy, leading to enhanced product quality and production efficiency.